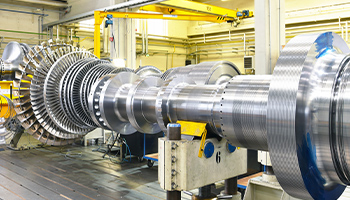

The OHC-800 has been introduced into various industrial sectors where calorimetric measurement is required, such as oil refining, steel industry, ship building, laboratories, universities, food industry, gas companies, turbine manufacturers, and glass manufacturers.

Calorific efficiency brings stability and greater energy output which leads to increased turbine life and furnace efficiency. Therefore leading to lower maintenance and running costs and increased financial returns.

Cost Reduction of fuel gas and stabilization of quality

Efficient reuse of steel by-product gas and improvement of the production efficiency by automating the operation of the furnaces properly

Efficient reuse of by-product gas

Accurate calorimetry of natural gas containing hydrogen

Stabilization of product quality and improvement of production efficiency

Real-time calorific value (CV) fiscal metering

* OIML R140 Class A Approval

Control and prevent engine knocking

Maintain efficient or accurate combustion

Measuring principle

Opt-Sonic method through measurement of light speed and sound speed

Measuring gas (*1)

CH4 basis Paraffinic Hydrocarbon gases as represented by Natural Gas (*2)

Measuring targets

Calorific value (Density / WOBBE index selectable)

Measuring range (*3)

Calorific value : 25.00 – 50.00 MJ/m3 (Gross, 0 degree C, 101.325kPa converted)

Density : 0.500~1.500 MJ/m3 (Specific gravity converted)

Measuring method

Constant-flow-rate gas introduction using external sampling devices

Display

Full-dot LCD (with backlight), 3 color LED lamp

External Output

4-20 mA DC (isolated, source current type) maximum load resistance of 300 Ω / RS-485 communication

Failure alarm

Low flow, Sensor unit abnormality, Low light amount

Failure alarm display

Lamp (red) / Content indication on LCD

Failure alarm contact (*4)

No-voltage contact 1a or 1b De-energize (Energize when alarming) or Energize (De-energize when alarming)

Contact capacity of 2 A, 30 VDC (resistance load)

Self-diagnostic function

FUNCTION CHECK (warm-up or maintenance mode), MAINTENANCE REQUIRED, OUT OF SPECIFICATION

Self-diagnostic display

FUNCTION CHECK, OUT OF SPECIFICATION : Lamp (orange) / Content indication on LCD

MAINTENANCE REQUIRED : Lamp (green) / Content indication on LCD

Self-diagnostic contact

(*4)

FUNCTION CHECK, OUT OF SPECIFICATION : No-voltage contact 1a or 1b

De-energize (Energize when alarming) or Energize (De-energize when alarming) Contact capacity of 2 A, 30 VDC (resistance load)

MAINTENANCE REQUIRED : SSR contact, contact capacity of 20 W, 240 VAC (resistance load)

Power supply

100 – 240 VAC ±10%, 50/60 Hz, max. 18 VA or 24 VDC ±10%, max.

5 W (The setting can be changed to either the AC or DC)

Ingress Protection level

Equivalent to IP66 and IP67

Operation temperature

-20 to+60 ℃ (-4 to +140 ℉)(ATEX / IECEx)/ -20 to+57 ℃ (-4 to +134.6 ℉)(Japan EX)

Operation humidity

95%RH or less (no condensing)

Outer dimensions / Weight

Approx. 286 (W) x 453 (H) x 150 (D) mm / Approx. 23 kg (50.7 lbs)

Explosion-proof structure

Flame-proof enclosures (Explosion-proof class: ExdⅡB+H2 T4 <Japan EX>/Ⅱ2GExdⅡB+H2T4 <ATEX/IECEx>)